System Maintenance Mastery: 7 Proven Strategies to Boost Efficiency

System maintenance isn’t just about fixing broken parts—it’s the backbone of smooth, reliable operations. Whether you’re managing IT networks, industrial machinery, or software platforms, proactive upkeep prevents costly downtime and extends system lifespan. Let’s dive into the essentials of effective system maintenance.

What Is System Maintenance and Why It Matters

System maintenance refers to the regular activities performed to keep systems—be it hardware, software, or mechanical—running efficiently and reliably. It’s not just a technical chore; it’s a strategic necessity across industries. From preventing data loss in IT environments to ensuring safety in manufacturing plants, maintenance keeps the wheels turning.

Defining System Maintenance in Modern Contexts

Today, system maintenance spans digital and physical domains. In IT, it includes patching software, updating security protocols, and monitoring server health. In industrial settings, it involves lubricating machinery, replacing worn parts, and calibrating sensors. The core goal remains the same: prevent failure before it happens.

- IT system maintenance ensures cybersecurity and data integrity.

- Industrial maintenance maximizes equipment uptime and safety.

- Software maintenance improves performance and user experience.

“Preventive maintenance is cheaper than emergency repair.” — Forbes

The Business Impact of Neglecting Maintenance

Ignoring system maintenance can lead to catastrophic outcomes. A 2023 report by Gartner revealed that unplanned downtime costs enterprises an average of $5,600 per minute. For manufacturing firms, a single hour of machine downtime can exceed $100,000 in losses. Beyond financials, poor maintenance damages brand reputation and customer trust.

- Increased risk of data breaches due to outdated software.

- Higher repair costs from delayed interventions.

- Reduced employee productivity from unreliable tools.

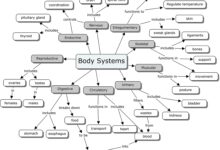

The 4 Core Types of System Maintenance

Understanding the different types of system maintenance helps organizations choose the right strategy. Each type serves a unique purpose and applies to different scenarios. Let’s explore them in detail.

Corrective Maintenance: Fixing What’s Broken

Corrective maintenance is reactive—it kicks in after a system fails. While unavoidable at times, relying solely on this approach is risky. It often leads to longer downtimes and higher costs. For example, if a server crashes due to a failed hard drive, corrective maintenance involves replacing the drive and restoring data from backups.

- Best for non-critical systems with low failure impact.

- Requires robust backup and disaster recovery plans.

- Can be combined with monitoring tools for faster response.

According to ISO 55000, corrective actions should be documented to prevent recurrence.

Preventive Maintenance: Staying Ahead of Failure

Preventive maintenance is scheduled upkeep designed to stop failures before they occur. This includes routine tasks like software updates, disk cleanups, and hardware inspections. For instance, replacing a server’s cooling fan every 18 months prevents overheating issues.

- Reduces unexpected breakdowns by up to 70%.

- Extends asset lifespan and maintains warranty compliance.

- Requires detailed maintenance schedules and checklists.

“An ounce of prevention is worth a pound of cure.” — Benjamin Franklin

Organizations using preventive strategies report 30% lower operational costs over five years, per McKinsey.

Predictive Maintenance: Using Data to Forecast Issues

Predictive maintenance leverages sensors, IoT devices, and machine learning to predict failures. By analyzing real-time data—like temperature, vibration, or power consumption—systems can alert technicians before a component fails. For example, a smart HVAC system might detect abnormal motor vibrations and schedule a service call.

- Uses AI and analytics for precision forecasting.

- Minimizes unnecessary maintenance tasks.

- High initial investment but strong ROI over time.

A study by PwC found predictive maintenance reduces maintenance costs by 25% and downtime by 35%.

Perfective Maintenance: Enhancing System Performance

Perfective maintenance focuses on improving system functionality and user experience. It’s common in software development, where updates optimize speed, add features, or improve interfaces. For example, upgrading a CRM system to support mobile access enhances usability for sales teams.

- Driven by user feedback and performance metrics.

- Supports long-term scalability and adaptability.

- Often integrated into agile development cycles.

This type ensures systems evolve with business needs, avoiding obsolescence.

Essential Tools for Effective System Maintenance

Modern system maintenance relies on specialized tools that automate monitoring, reporting, and repairs. Choosing the right tools can dramatically improve efficiency and reduce human error.

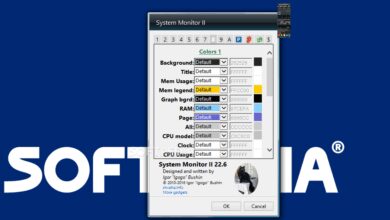

Monitoring and Alerting Software

Tools like Nagios, Zabbix, and Datadog provide real-time visibility into system health. They monitor CPU usage, memory, network traffic, and application performance, sending alerts when thresholds are breached.

- Enable proactive responses to potential issues.

- Support integration with ticketing systems like Jira.

- Offer customizable dashboards for different teams.

For example, Datadog allows IT teams to track cloud infrastructure across AWS, Azure, and Google Cloud.

Asset Management Systems

Asset management tools like ServiceNow and IBM Maximo track the lifecycle of physical and digital assets. They store maintenance histories, warranty details, and replacement schedules.

- Ensure compliance with regulatory standards.

- Streamline procurement and inventory management.

- Facilitate audit readiness and reporting.

These systems are critical for industries like healthcare and aviation, where equipment reliability is non-negotiable.

Automation and Scripting Tools

Automation reduces repetitive tasks. Scripts in Python, PowerShell, or Bash can automate backups, log rotations, and patch deployments. Configuration management tools like Ansible and Puppet standardize system setups across environments.

- Reduce human error in routine operations.

- Ensure consistency across servers and devices.

- Free up IT staff for higher-value tasks.

“Automation is the key to scalable maintenance.” — TechTarget

Best Practices for Implementing System Maintenance

Even the best tools fail without a solid strategy. Implementing effective system maintenance requires planning, training, and continuous improvement.

Create a Comprehensive Maintenance Plan

A maintenance plan outlines what needs to be done, when, and by whom. It includes schedules, checklists, escalation procedures, and resource allocation. For example, a monthly server maintenance window might include patching, log reviews, and performance tuning.

- Align maintenance windows with low-usage periods.

- Document all procedures for consistency.

- Review and update the plan quarterly.

The U.S. Department of Energy recommends using Maintenance Best Practices guides for federal facilities, which are also applicable to private sectors.

Train and Empower Your Team

Skilled personnel are the backbone of any maintenance program. Regular training ensures staff stay updated on new technologies and safety protocols. Cross-training improves resilience during absences or emergencies.

- Offer certifications in ITIL, CMMS, or Six Sigma.

- Encourage knowledge sharing through internal wikis.

- Recognize and reward proactive problem-solving.

Companies with formal training programs see 40% fewer maintenance-related incidents, according to ASQ.

Leverage Data for Continuous Improvement

Data-driven decisions transform maintenance from a cost center to a strategic asset. Track KPIs like Mean Time Between Failures (MTBF), Mean Time to Repair (MTTR), and Overall Equipment Effectiveness (OEE).

- Use dashboards to visualize trends and anomalies.

- Conduct root cause analysis after major failures.

- Adjust strategies based on performance data.

For instance, if MTTR is increasing, it may indicate a need for better spare parts inventory or technician training.

System Maintenance in IT vs. Industrial Environments

While the principles of system maintenance are universal, implementation varies significantly between IT and industrial settings.

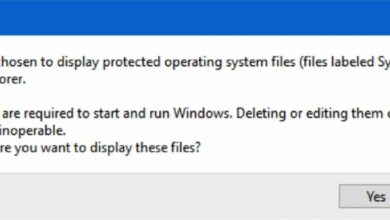

IT System Maintenance: Securing the Digital Backbone

In IT, maintenance focuses on data integrity, cybersecurity, and service availability. Key activities include:

- Applying security patches within 48 hours of release.

- Conducting regular vulnerability scans.

- Testing disaster recovery plans quarterly.

Cloud environments add complexity, requiring coordination between internal teams and providers like AWS or Microsoft Azure. Tools like Amazon CloudWatch help monitor cloud resources in real time.

“90% of cyberattacks exploit known vulnerabilities that could have been patched.” — CISA

Industrial System Maintenance: Keeping Machines Running

In manufacturing, maintenance ensures machinery operates safely and efficiently. Techniques include:

- Lubrication and alignment of moving parts.

- Thermal imaging to detect electrical hotspots.

- Vibration analysis for rotating equipment.

Failure in industrial systems can lead to safety hazards. For example, a malfunctioning pressure valve in a chemical plant could cause an explosion. Therefore, compliance with OSHA and ISO standards is critical.

The OSHA Process Safety Management standard mandates regular inspections and employee training.

The Role of AI and IoT in Modern System Maintenance

Artificial Intelligence (AI) and the Internet of Things (IoT) are revolutionizing system maintenance. These technologies enable smarter, faster, and more accurate interventions.

AI-Powered Predictive Analytics

AI models analyze historical and real-time data to predict equipment failures. For example, an AI system might detect subtle changes in a turbine’s vibration pattern, signaling an impending bearing failure weeks in advance.

- Reduces false alarms compared to rule-based systems.

- Adapts to changing operating conditions.

- Integrates with CMMS for automated work orders.

Google’s DeepMind has used AI to reduce data center cooling costs by 40%, showcasing the potential of intelligent maintenance.

IoT Sensors for Real-Time Monitoring

IoT devices collect granular data from machines and environments. A single factory floor might deploy hundreds of sensors tracking temperature, humidity, pressure, and motion.

- Enable remote monitoring of geographically dispersed assets.

- Support condition-based maintenance instead of fixed schedules.

- Integrate with cloud platforms for centralized analytics.

Siemens uses IoT in its Digital Enterprise suite to optimize production lines globally.

Challenges and Considerations

Despite their benefits, AI and IoT introduce challenges:

- High upfront costs for sensors and infrastructure.

- Data privacy and cybersecurity risks.

- Need for skilled personnel to manage and interpret data.

Organizations must balance innovation with risk management, ensuring systems are secure and compliant.

Cost-Benefit Analysis of System Maintenance Programs

Investing in system maintenance isn’t just about avoiding problems—it’s about creating value. A well-structured program delivers measurable financial and operational returns.

Direct Cost Savings

Preventive and predictive maintenance reduce repair expenses by catching issues early. For example, replacing a $200 sensor before it fails prevents $20,000 in downtime and collateral damage.

- Lower energy consumption from well-maintained equipment.

- Reduced need for emergency overtime labor.

- Fewer replacement parts due to extended asset life.

A study by the U.S. EPA found that proper maintenance cuts energy use in commercial buildings by 10–20%.

Indirect Benefits

Beyond cost savings, maintenance improves safety, compliance, and customer satisfaction.

- Fewer workplace accidents due to reliable equipment.

- Avoidance of regulatory fines for non-compliance.

- Higher customer retention from consistent service delivery.

“Every dollar spent on maintenance saves $4 in future repairs.” — Facility Maintenance Decisions

Calculating ROI

To calculate return on investment (ROI), use the formula:

ROI = (Total Savings – Total Costs) / Total Costs × 100

For example, if a predictive maintenance program costs $100,000 annually but prevents $350,000 in downtime and repairs, the ROI is 250%.

Tools like IBM Maximo include built-in ROI calculators to help justify investments.

What is the difference between preventive and predictive maintenance?

Preventive maintenance follows a fixed schedule (e.g., servicing a machine every 6 months), regardless of its actual condition. Predictive maintenance, on the other hand, uses real-time data and analytics to determine when maintenance is actually needed, making it more efficient and cost-effective.

How often should system maintenance be performed?

The frequency depends on the system type and usage. Critical IT systems may require daily monitoring and weekly updates, while industrial equipment might need monthly inspections. Always follow manufacturer guidelines and industry standards.

Can small businesses benefit from system maintenance programs?

Absolutely. Even small organizations can use low-cost tools like open-source monitoring software and cloud-based CMMS to implement effective maintenance. The key is consistency and documentation.

What are common mistakes in system maintenance?

Common mistakes include skipping routine checks, failing to document repairs, ignoring user feedback, and not training staff properly. Another major error is relying solely on reactive maintenance instead of adopting preventive strategies.

Is system maintenance necessary for cloud-based applications?

Yes. While cloud providers handle infrastructure maintenance, businesses are still responsible for updating their applications, managing access controls, and monitoring performance. Regular audits and security checks are essential.

System maintenance is far more than a technical checklist—it’s a strategic discipline that safeguards operations, reduces costs, and drives long-term success. By understanding the types, tools, and best practices, organizations can build resilient systems that adapt to changing demands. Whether you’re managing servers or factory floors, a proactive approach to maintenance pays dividends in reliability, safety, and efficiency. The future belongs to those who maintain not just to survive, but to thrive.

Recommended for you 👇

Further Reading: